Plasma etching

Attacking with reactive ions is a technology employed in micro and nanomanufacture with characteristics that differ from conventional wet chemistry techniques. With this type of attack low-pressure (high-vacuum) plasma is generated using an electromagnetic field. The high-energy plasma ions attack the surface of the substrate and react with it.

At TEKNIKER selective attacks are carried out with silicon, oxides and nitrides on substrates of up to 4 inches employing an inductively-coupled plasma, employing various gases (SF6, C4F8, CHF3, and so on). It is also possible to undertake cleaning processes, eliminating the remaining layer in NIL processes, and activating surfaces using oxygen plasma.

The most outsourcing characteristics are the following:

- Physical-chemical process in which the isotropy/anisotropy is controllable.

- Great range of materials to attack.

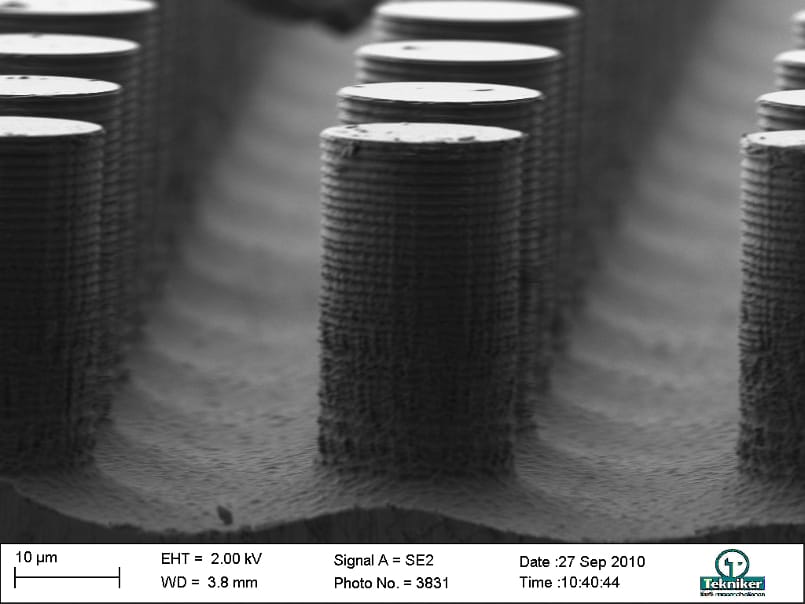

- Possibility of deep attacks using the Bosch process (plasma attacks and passivation alternatives).