Manufacture of moulds for the production of disposable microfluidic cartridges

To manufacture moulds for the production in series of disposable microfluidic cartridges in polymer using hot embossing and casting.

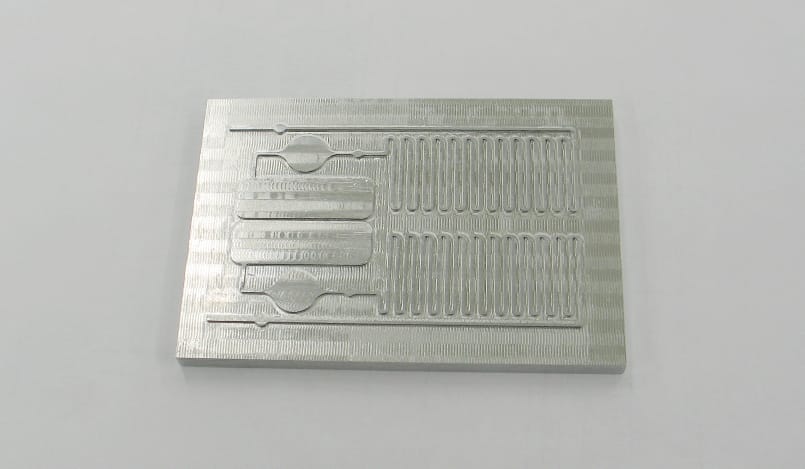

The manufacture of two inserts in aluminium with microfluidic features for the production of disposable cartridges in PMMA and PDMS.

Point of Care (POC) immediate diagnosis/self-diagnosis is aimed at reducing the time necessary for the diagnosis of illnesses.

Existing technologies require sending patients’ samples to a certified laboratory of reference, being a slow and complicated process for identifying a disease.

Moreover, this can mean, for example, multiple visits of the patient to the doctor. The miniaturisation of laboratory protocols has many advantages over traditional methods: reducing the diagnosis time, the reduction of costs, reducing the volume of reagents, portability, the comfort of the patient, etc.

As a result of interest by the Department of Electronic and Computer Engineering at London’s Brunel University in devising a portable device capable of accepting a sample taken directly from the patient and providing the diagnosis of a specific illness in a matter of minutes instead of days, and based on disposable cartridge samples, the first step was put forward for the manufacture of moulds for the production in series of disposable microfluidic cartridges in polymer using hot embossing and casting.

Tekniker is working jointly on this manufacture of moulds/inserts with microfluidicstructures in aluminium using a micromilling process.

As a result, two inserts were manufactured, one for cartridges in PMMA employing hot embossing, and another for PDMS cartridges by casting, in accordance with the specifications regarding product and process.