Industry 4.0 to facilitate inclusion in employment

The Tekniker technology centre is coordinating an employment inclusion programme based on new technologies to adapt advanced manufacturing environments to individual skills.

Data published in December 2021 by INE (the Spanish Statistics Office) showed that there were 1,933,400 working-age (16 to 64) disabled people in Spain, although only 34.3% (663.900) were actually working. According to the Employment Report on Disabled People, it is in the industrial sector where more active people with disabilities can be found.

It is this context where the advent of new manufacturing technologies such as, for instance, augmented reality or collaborative robotics, can significantly facilitate inclusion in employment for this collective in a sector where very specific and specialised worker profiles are required to perform many tasks.

The Tekniker technology centre, a member of the Basque Research and Technology Alliance (BRTA), an organisation with extensive knowledge related to the aforementioned advanced solutions that can be applied in the industry, is currently coordinating the European CMT4ALL project (Collaborative Manufacturing Tasks for All Workers) to develop collaborative technologies for their versatile integration in a number of 4.0 manufacturing scenarios.

Johan Kildal, a Tekniker researcher, explains that “our goal does not only consist in making it easier to access industrial jobs, but to also allow workers to receive training and acquire new skills to become less dependent on the support offered by certain technologies”.

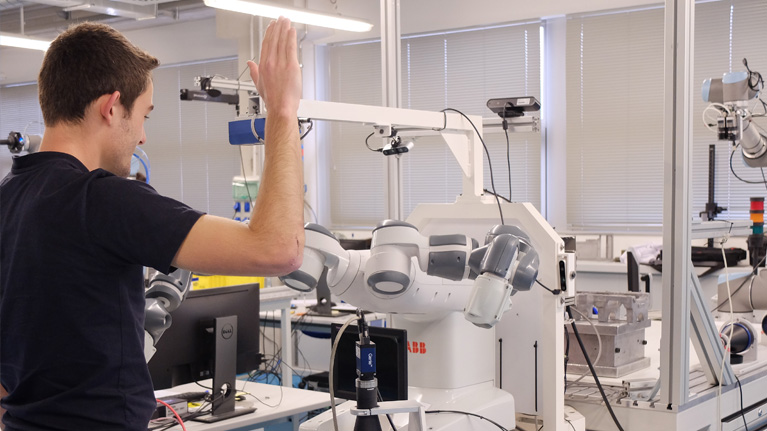

Consequently, collaborative technologies developed for this purpose are focused on collaborative robotics, augmented reality, interfaces for natural communication (voice and gestures) as well as artificial vision and intelligence. It must be underscored that the ultimate goal is not to create a manufacturing cell featuring a certain type of configuration, but rather to develop a modular design allowing for the integration of the previously mentioned technologies to perform very diverse operations and make them accessible to workers characterised by different profiles. One of the key elements to achieve this outcome is called “design-for-all”, whose aim is to minimise the amount of knowledge a worker has to acquire to use technology by making it possible, for instance, to speak to the robot instead of having to programme a unit. The ultimate goal is to complement the skills required by workers as a function of each individual profile.

In this manner, and thanks to the design-for-all approach, the project will be able to change the traditional acquisition model used in the industrial setting by implementing tools that are fully adapted to the requirements and capabilities of each individual profile.

The project addresses the challenge of implementing more resilient working environments. From a society perspective, moreover, the cell will facilitate the inclusion of all of its members in economic activities and foster equal opportunities.

Lastly, three use cases will be developed during the initiative with the help of other project partners to validate and test the work cell, namely, a product preparation scenario at ADTP (France) involving workers with intellectual disabilities, jointly developed with INP (the University of Grenoble); an elevator assemblage space at KLEEMANN (Grecia) with workers with no disabilities and developed together with LMS (University of Patras); and, finally, a manufacturing environment where small parts are produced at ALFA MIM-TECH by workers with physical disabilities, jointly developed with Tekniker.

In this latter case, Tekniker is working closely with ALFA MIM-TECH to improve the physical and cognitive ergonomics of its workers in a specific area of the firm’s production process. The technology centre is addressing the problem by developing a cell based on a two-armed robot that will allow workers to avoid the most demanding stages of an operation. The robot is equipped with a sophisticated vision system which, by means of artificial intelligence, can monitor worker actions and adapt to their pace of work. The robot, moreover, monitors the quality of the work that has been done and reports any errors to take joint corrective actions. The resulting process delivers traceability for all the operations that have been performed.

Collaborative robotics, augmented reality, artificial vision combined with artificial intelligence or natural interaction interfaces are some of the most outstanding technologies to be applied in different industrial environments.

CMT4ALL (Collaborative Manufacturing Tasks for All Workers) is a European project funded by EIT Manufacturing under the coordination of Tekniker with partners from France, Greece and Spain.