A technological boost to incorporate laser technology into European industrial production

Tekniker participates in the LaserWay project whose aim is to replace conventional production methods with high-performance production lines based on high-speed laser manufacturing processes that are more resilient and sustainable.

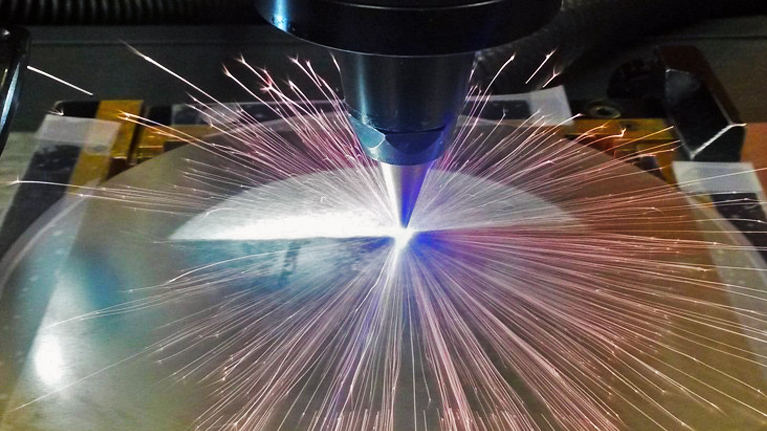

Laser technology is a highly resilient and adaptable solution used to address manufacturing challenges. Compared to rigid conventional processes designed to deal with large volumes, laser-based systems offer unique versatility and can be applied to an extensive range of industrial applications. Although improvements are currently underway to increase operating speeds to match processes such as pressing, laser offers a great potential to transform production by delivering more accuracy, increased energy efficiency and adaptability. Once fully developed, it will become a key element in the industry of the future.

It is in this scenario that Tekniker, a Basque technology centre and member of the Basque Research and Technology Alliance (BRTA), is actively involved in the European LaserWay project to address the challenge of developing new high-speed laser micro-perforation processes that are sustainable, resilient and innovative.

Within the scope of this project, Tekniker’s main goal consists in developing a single pulse laser micro-perforation process that is highly productive and efficient by carrying out research focused on beam shaping, machine design, process optimisation and the development of in-process monitoring control devices.

Tekniker researcher Carlos Soriano underscores that “one of the most disruptive activities currently underway involves designing, manufacturing and fitting a new laser micro-perforation head with dynamic beam shaping capabilities to ensure geometric hole circularity above 600 holes/second”.

Micro-perforation applications

Thanks to a number of technological developments associated with the project, Tekniker will modernise and double the productivity of a micro-perforation machine developed within the framework of previous projects. This unit, currently available at Tekniker’s facilities, will incorporate laser technology to be applied in two areas: to the production of metallic filters for the water filtering industry and to the manufacture of micro-perforated leading edges featuring hybrid laminar flow control for aeronautics to drill millions of holes that will significantly enhance process productivity levels.

Once fully processed, all components shall be tested and validated under real operating conditions to ensure that the specifications defined by the sectors involved meet quality standards in full.

The success of the project will offer a competitive advantage to the industries involved as it will not only reduce processing time significantly, but also optimise how materials are used and improve the quality of end products. All the progress made, moreover, will help to boost innovation in the area of high-speed laser processing and reinforce Europe’s standing as a world leader in the area of advanced manufacturing technologies.

LaserWay’s technological advancements are being showcased this week in France during the 18th edition of the International High Speed Machining Forum. Along with contributing to the conference program, Tekniker is actively involved as a member of both the organizing and scientific committees of this event, which is dedicated to the latest innovations in machining technologies.

More about the LaserWay project

With more than 5 million Euros in funding from the EU Horizon programme, Laserway features a consortium of 16 partners from Spain, Germany, the Czech Republic, Italy, Netherlands and France.

Ending in December 2026, the project intends to develop a more sustainable way of producing car components and reducing waste in the automotive sector. Efforts will also focus on increasing aircraft fuel efficiency by lowering drag forces, reducing toxicity and contamination in brake disc coating processes and developing highly efficient water filters to help clean up rivers and oceans.

This project has received funding from the European Union´s Horizon Europe research and innovation programme under grant agreement No 101138739.