Tekniker (Eibar)

Developing a broader vision of the concepts that make it possible to manage the equipment, patterns and measuring processes used by companies more efficiently is the main focus of the “Industrial Metrology and calibration” course organised by Tekniker that will take place on November 20 at the technology centre’s facilities.

Aims

Aimed to

Technicians responsible for controlling and calibrating measuring equipment and carrying out measuring procedures. Equally suitable for people dealing with quality management issues, manufacturing and technical office activities.

Conditions

* As seating capacity is limited, registrations will be processed on a first come, first served basis.

CONTENTS

Introduction. What is calibration and why does measuring equipment have to be calibrated?

Requirements listed in standards UNE-EN ISO-9000, UNE-EN ISO-9001, UNE EN 9100, UNE EN ISO/IEC 17025, IATF 16949, UNE 66180, ISO 10012, UNE-EN ISO 14253-1 and UNE-EN ISO 14253-2.

Dissemination and traceability of measurements. Traceability chain, certified laboratories and documentation.

Uncertainty and how to calculate it. Prior definitions (exactness, precision, correctness, uncertainty, etc.).

Causes of uncertainty. Calculating uncertainty on measuring equipment (with working examples).

Equipment acceptance criteria. Calibration certificates, tolerances and specifications.

Interpreting and digitising calibration certificates.

LABORATORY PRACTICES

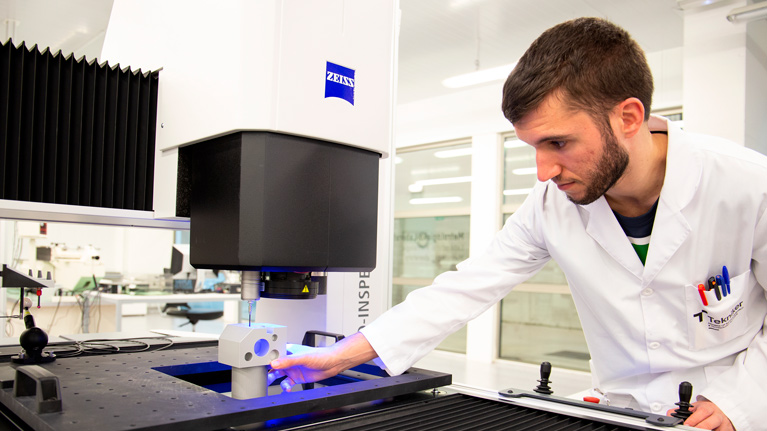

Metrology practices will be carried out in a laboratory setting to apply the knowledge resulting from tests and measurements carried out with diverse equipment and instruments.