Machine Tools and Manufacturing

Design, simulation, control, validation and measurement of machines

Manufacturing processes and resources

Process optimisation. Digital twin

Connected machine tools: Industry 4.0

Tekniker´s offer for the machine tool and manufacturing sector encompasses the following areas:

DESIGN, SIMULATION, CONTROL, VALIDATION AND MEASUREMENT OF MACHINES

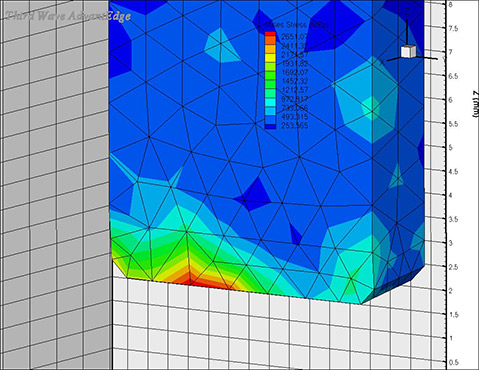

- Static, dynamic and thermal calculation and mechanical (multibody) simulation.

- Development of a "virtual machine” to model and simulate machine-process to drastically shorten the fine-tuning required for new processes.

- 3D design of different kinds of machines (millers, borers, grinders, lathes, injection machines, parallel kinematics, micro millers, multi-functional machines, presses, etc.), or components (headers, electro-spindles, hydrostatic sustentation, guiding fitted with linear motors, etc.).

- Regulation and optimisation of control loops on mechatronic systems.

- Metrological checking, measurement and compensation of volumetric errors.

- Developments connected to specific software.

MANUFACTURING PROCESSES AND RESOURCES

- Manufacture, assemblage and fine-tuning of machine tool prototypes.

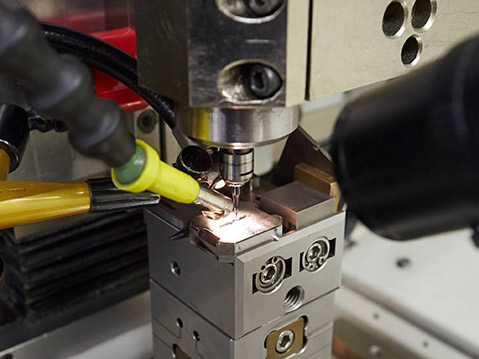

- Development of conventional machining processes: turning, milling, boring, grinding, electro-erosion, ultrasounds, laser and electrochemical. Process optimisation, simulating machining, machine collisions and development of post-processors, hard machining and design of cutting tools. Ecological machining (MQL, cold air, CO2, NL). Machining with high pressure cutting oil (140 bar). Training actions addressing cutting technologies.

- Development of non-conventional manufacturing processes: electrochemical machining, electro-erosion and ultrasounds.

- LMD (Laser Metal Deposition) additive manufacturing.

- Micro-manufacturing (milling, turning and electro-erosion) and laser machining to produce functional surfaces.

- Optimisation of lubrication and cooling systems to improve processes and reduce wear.

PROCESS OPTIMISATION. DIGITAL TWIN

- Development of simulation models that include the machine, the monitoring and processing of external and internal signals as a source of optimisation for any models used: “digital twin”.

- Process optimisation based on simulation models incorporating machine control to take decisions in a smart and autonomous manner related to process parameters and dynamic conditions of any mechanical components involved. This includes capacity to monitor a machine´s OEE (“Overall Equipment Efficiency”) on a real time basis so operators can be made aware of possible trends to anticipate potential incidents at all times. Operators may also ascertain root causes connected to efficiency losses by searching for correlations between OEE and the different variables associated with its components (efficiency, availability and quality) by using statistical tools and data mining.

- Flexible and reconfigurable automation that, for instance, allows parts to be loaded and unloaded in production contexts in which parts are changed frequently or parts arrive at the machine in containers or for on-site measuring to be performed.

- Inspection robots and systems (vision, contact, etc.) to automate manufacturing processes. Collaborative robotics.

CONNECTED MACHINE TOOLS: INDUSTRY 4.0

- “Health assessment” of a machine. Based on a number of characterisation tests (Fingerprint tests), the machine provides quasi-continuous real-time information on the status of its different critical components. This can be complemented by machine tool self-calibration mechanisms so that in a matter of only a few minutes and in a fully autonomous manner it can check machine errors and, should anything be out of tolerance, the unit can calibrate itself to continue machining with greater accuracy.

- Monitoring the machine´s local health status. Associated data can be exchanged with the maker of the machine to offer added value services (servitization) in the form of predictive maintenance services.