Tekniker presents laser technologies for advanced manufacturing in Bilbao

The technology centre will have a stand at the international MESIC conference organised by the society of manufacturing engineering to be held at Bizkaia Aretoa from June 18 – 20. Tekniker, a sponsor of the event, will present the results of European and Spanish R&D projects featuring applications ranging from agriculture to aeronautics.

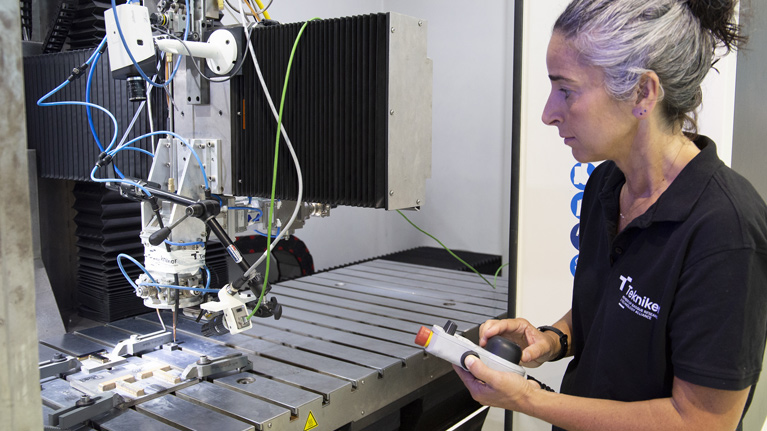

Both the knowledge and expertise of the Tekniker technology centre, a member of the Basque Research and Technology Alliance (BRTA), and its new laser technologies will have an outstanding presence at MESIC 2025, the international conference organised by the society of manufacturing engineering. The 11th edition of this event where the most recent scientific and technological developments related to advanced manufacturing will be presented will take place in Bilbao at Bizkaia Aretoa from June 18 - 20.

Tekniker will not only sponsor the event but also have a stand in the exhibition area to display the results of European and Spanish R&D projects that use and apply laser manufacturing processes to surfaces, structures or parts.

An outstanding example can be found in the form of a demonstrator featuring a surface texturised by these technologies under the umbrella of the INFUNDA project funded by the Spanish Ministry of Science & Innovation within the framework of the National Strategic Corporate Research Programme (CIEN).

Thanks to the properties generated, surfaces can be easily cleaned. This is what makes the process highly suitable for the agricultural and healthcare sectors. It also demonstrates the potential associated with implementing texturing techniques featuring ultra-short laser pulses to be eventually commissioned at companies with large scale manufacturing operations involving polymeric containers for the food or automotive business.

Julen Molinuevo, a Tekniker researcher, explains that “as the most innovative feature is that textures can be transferred to complex 3D parts, this significantly widens the range of potential uses for laser textures of this kind. The type and size of a texture, moreover, can be adapted to the specific features of an application, as occurs with anti-ice or antibacterial surfaces”.

Results of European projects

The technology centre will also showcase the results of EU-funded initiatives such as LASERWAY or IAM4RAIL within the framework of the Horizon Europe programme.

In the case of the former, metallic filters perforated by laser technology used for water treatment are currently being developed. In the latter, a steel block has been produced to run trials on rolling stock wheels using wire-based laser metal deposition (DED-LB/MW).

Tekniker’s list of demonstrators at MESIC 2025 will display an automotive disc brake featuring a ceramic coating produced by high-speed laser overlaying technique within the scope of project MARTE, funded by NextGeneration as well as an aeronautical titanium structure produced on TITAN, an innovative controlled-atmosphere additive manufacturing machine originating from the Basque Government’s EDISON project and Elkartek programme.

Tekniker’s scientific excellence in this particular area, moreover, will be supported by the publication of two its in-house studies in the conference’s official journals addressing, firstly, the results obtained in the aforementioned INFUNDA project and, secondly, research actions geared towards monitoring and analysing the quality of the DED-LB/MW process.

The Tekniker researcher Jon Flores, points out that “our findings show the potential associated with data-based methodologies to understand how manufacturing processes evolve and improve quality analysis capabilities. They also provide the foundations required to advance towards a DED process that is more reliable and provides a knowledge base for future developments in terms of optimising processes and assuring quality”.