A technological partnership to accelerate R&D in the area of green hydrogen

Tekniker collaborates with the Spanish start-up H2Greem to address the sector’s challenges.

In order to reinforce the organisation’s position as a key technological partner in the development of new sustainable technologies that will help to decarbonise the industry, Tekniker has set up a strategic collaboration with the Spanish start-up H2Greem focused on technologies and products related to generating green hydrogen.

This strategic partnership will allow both parties to share the resources and knowledge required to meet the sector’s challenges and requirements for the ultimate purpose of facilitating and accelerating the application of new hydrogen production technologies in the energy market.

The main goal of this partnership is to boost research and industrial scaling for Proton Exchange Membrane (PEM) electrolysers to produce green hydrogen at competitive prices.

Electrolysers are devices that use a chemical process (electrolysis) to produce hydrogen that separates hydrogen and oxygen molecules that water is made up of by applying electricity.

PEM technology offers major advantages such as the purity of the hydrogen it produces and the ease with which hydrogen can be incorporated to renewable energy plants.

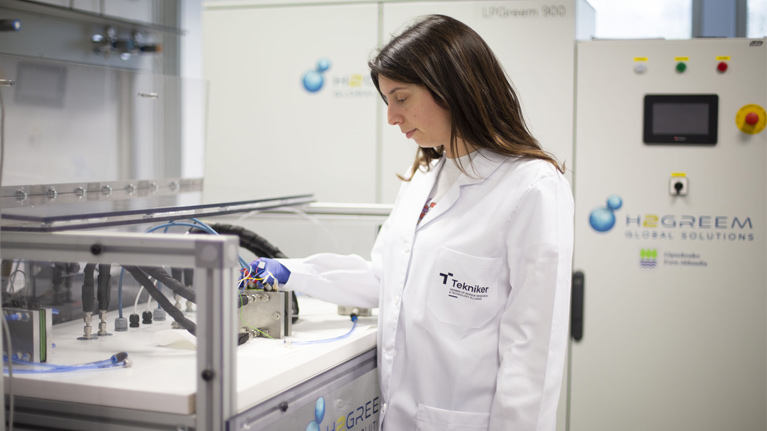

Equipment developed by H2Greem

Tekniker has several pieces of equipment developed by H2Greem used to study materials and components and establish the best combination required to manufacture these energy generation systems.

Eva Gutierrez, a Tekniker researcher and an expert in the area of hydrogen technologies, says that “we have analysed the performance of new PEM electrolyser configurations under real operating conditions on a 1 kW test bench manufactured by H2Greem. Moreover, and in order to optimise other generator systems and control algorithms, we also own a 5kW electrolyser demonstrator made by the start-up.”

H2Greem is a technological firm that originally emerged from the area of innovation and intra-entrepreneurship at Enagás (Enagás Emprende) dedicated to developing, manufacturing and marketing hydrogen generators based on PEM technology. It is the only Spanish manufacturer that possesses in-house technology to propose integral PEM electrolyser solutions.

Adapting to the market

The collaboration in which Tekniker and H2Greem are involved will serve to boost Tekniker’s commitment with regard to green hydrogen and will allow the technology centre to obtain first-hand information on market needs so that the organisation’s research activities can be adapted accordingly.

Tekniker’s approach encompasses activities reaching out to the entire value chain of green hydrogen, i.e.: generation, storage, transport as well as mobility and industrial applications.

Eva Gutierrez also underscores that “our knowledge in this sector and several other closely associated technologies allow us, among other things, to analyse how feasible it is to bring together electrolysers and hybrid renewable energy plants to produce green hydrogen, to research new organic fluids used to store and transport hydrogen or to establish which materials are compatible to manufacture hydrogen generators”.

Tekniker is a partner of the Basque Hydrogen Corridor (BH2C) led by Petronor as well as an active member of the Hydrogen Europe Research group and the Hydrogen Task Force of the Sectoral Hydrogen Forum of the Basque Country’s Energy Cluster. The organisation also forms part of the Spanish Hydrogen and Fuel Cell Association (PTE-HPC).

Using as a basis the extensive amount of knowledge accumulated in this area, Tekniker has been involved in several projects supported by European, national and local funding as well as in several direct collaborative actions with the industry.

More about H2Greem

H2Greem boasts an outstanding team of experts dealing with hydrogen technologies that is led by Mario Carrero. Their activities cover the entire hydrogen value chain, from project development to the selection of locations plus engineering, product integration, in-situ installation work, operation and maintenance.