Smart glass for the railway sector

The Tekniker technology centre and the glass manufacturer Ariño Duglass are participating in the VITECA project whose goal is to apply innovative coating techniques to windscreens and windows for the railway industry.

The use of smart glass that responds actively to external stimulations and is extensively used in sectors such as the automotive and architectural sectors is now gaining ground in the railway industry thanks to the incorporation of features that deliver greater comfort for passengers and reduce power consumption. It has been estimated, moreover, that this market will grow between 12-15% annually over the next few years and that transport will become one of the biggest consumers.

It is in this context that the Tekniker technology centre, a member of the Basque Research and Technology Alliance (BRTA), and the glass manufacturer Ariño Duglass, are collaborating in the VITECA project (Vidrio inTEligence para ferroCArril manufactured by means of Sputtering techniques).

The aim of the initiative is to develop two types of smart glass for the railway industry in the form of heatable glass to which voltage is applied in order to confer de-icing and de-misting properties and electrochromic glass that changes optical transmission properties to become opaque as a result of applying a certain amount of voltage.

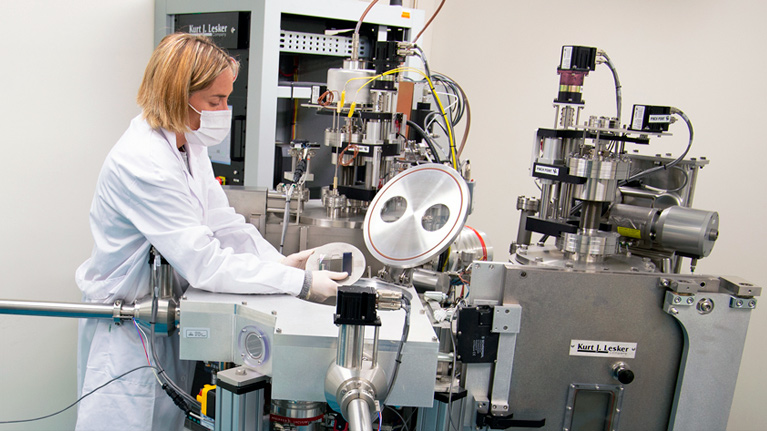

In order to do so, Tekniker, an organisation boasting 30 years of experience in the field of surface engineering, will contribute its knowledge related to depositing functional layers by means of the magnetron sputtering technique, whilst Ariño Duglass will apply the coatings obtained to large glass components.

More specifically, two parallel developments have been addressed within the scope of the project: the development of heated railway windscreens and electrochromic windows to improve passenger comfort.

Windscreens with de-misting and de-icing properties

As regards glazing used on rolling stock, windscreens for locomotives must meet a number of special requirements. Due to the high speed reached by these vehicles, windscreens must incorporate a high level of shock resistance whenever speeds of 160 Km/h are exceeded.

Windscreens, moreover, must also perform their usual functions in the form of high transparency levels, absence of reflected second images, minor optical distortions, no changes in colours seen in transmission, etc. Another functional requirement that applies to the railway industry is that windscreens must be equipped with de-misting or de-icing systems to spread heat evenly throughout the entire surface of the glass. Nowadays, most train windscreens incorporate a heating feature that is provided by several tungsten threads embedded in the plastic sheet of polyvinyl butyral (PVB) joining both glass components that form the windscreen itself.

As regards the VITECA project, Tekniker proposes that layers of transparent conducting oxides (TCO) deposited by magnetron sputtering be used instead of tungsten threads to heat windscreens more uniformly and prevent the formation of hot spots that could potentially alter the optical properties of a windscreen and create areas of distortion for drivers.

Arin?o Duglass and Tekniker will develop a new windscreen that includes the deposition of a TCO layer as well as the anti-spalling treatment required to meet shock resistance requirements.

Windows that change their colour

In the railway industry, power consumption is crucial as more than a third is used to provide heating and air conditioning for passengers and lateral windows are the main source of power losses. A so-called “low-emissive type of glass is currently available on the market to prevent the penetration or emission of infrared radiation aboard trains, the loss of heat or cold and significantly reduce power consumption levels with regard to heating or air conditioning. Glass of this kind, however, cannot alter visible radiation nor change colour.

It is within the framework of the VITECA initiative that Tekniker intends to develop windows based on electrochromic glass made up of several layers deposited by magnetron sputtering that can be easily taken to an industrial scale at Arin?o’s facilities.

The specific feature of electrochromic glass is that it can change its light transmission properties when a small electric current is applied. Smart materials of this kind allows users to control the amount of light (and, consequently, the amount of heat) they transmit to achieve significant energy savings. Once activated, the glass transitions from transparent to opaque to partially block sunlight although it always offers a clear view and passengers only have to press a button to change window settings for greater comfort.

The VITECA project has been promoted by the Spanish Ministry for Science and Innovation via the National Programme of Collaborative R&D&I Challenges.

This project has an impact on SDG 9 - Industry, innovation and infrastructure and SDG 12 - Responsible production and consumption, contributing towards the economic, social and environmental pillars of sustainable development, and, ultimately, on society at large.