Shared data spaces to boost servitization in the European industry

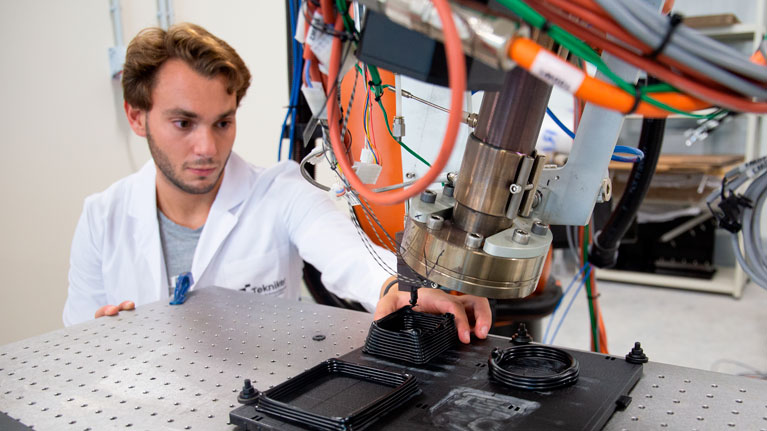

The Tekniker technology centre is currently involved in Tech4MaaSEs, a European project that is addressing the challenge of implementing a network of advanced technologies to further cooperation in the area of advanced manufacturing in Europe.

The purpose of business models based on sharing assets is to intensify the use of goods (cars, dwellings…) that are not continuously utilised. In our daily lives, BlaBlaCar or Airbnb offer two clear examples.

As regards the industry, these shortcomings can be found at source in the case of production machines that do not operate 24 hours a day. Manufacturers frequently outsource processes to very distant companies and are unaware that there are other firms in their environment that, although they own the same production resources, are underusing their machines.

It is in this context that the Manufacturing as a Service (MaaS) concept was born in Europe to maximise the utilisation of production resources and minimise the carbon footprint associated with transport.

The ultimate goal of servitizing manufacturing resources is to significantly enhance the resilience and reactive capacity of resources to implement productivity upon demand covering numerous product categories.

It is an approach in which different agents come into play. Suppliers of manufacturing systems and integration technologies design and offer interoperable services in close cooperation with manufacturing firms, whilst other suppliers in the value chain can offer additional services.

Although secure real-time data exchanges between the parties involved are associated with rapid responses, more research is required to improve the overall system.

Since 2024, the Tekniker technology centre has been involved in Tech4MaaSEs, a European initiative addressing the challenge of implementing a network of digital twins equipped with trustworthiness and cognition features to allow European advanced manufacturing to cooperate in a distributed manner within the scope of different value networks.

The project, funded by the European Union’s Horizon programme, brings together knowledge connected to manufacturing processes and the most recent developments associated with ICTs.

On the one hand, it features a powerful data space component. On the other, the project intends to use artificial intelligence (AI) tools to perform a task that, until now, has been carried out by highly experienced people from the manufacturing sector to establish the sequence of processes to be followed when manufacturing components.

Jon Ander Sarasua, a Tekniker researcher, explains that “if a user accesses the MaaS platform to hire manufacturing services, the system will establish (based on the file provided by the customer) the sequence of processes involved (like, for instance, additive manufacturing, milling, grinding, etc.) as well as other associated services provided by the value chain”.

Nowadays, this is done by production staff who analyse the drawings, tolerances and materials of the part to be manufactured. When applied to the world of AI, the analysis specifically detects a part’s most salient features to associate them with a specific sequence of processes in such a manner that the platform can provide a catalogue of companies that offer these manufacturing processes and list them based on criteria such as, for instance, physical proximity, lead times and price.

It is within the framework of this project that Tekniker is collaborating with a mould manufacturer and a customer/user from the injection sector in a pilot project addressing the issue of plastic injection moulding.

The pilot comprises three companies that can represent different roles in relation to a MaaS approach (consumers and suppliers of manufacturing services) and exemplify different business cases that are highly representative of the industrial environment.

The pilot also includes three different types of services: Additive manufacturing that may or may not include finishing, machining and plastic injection processes.

This project has received funding from the European Union’s Horizon Europe research and innovation programme under grant agreement N.: 101138517. DOI: 10.3030/101138517