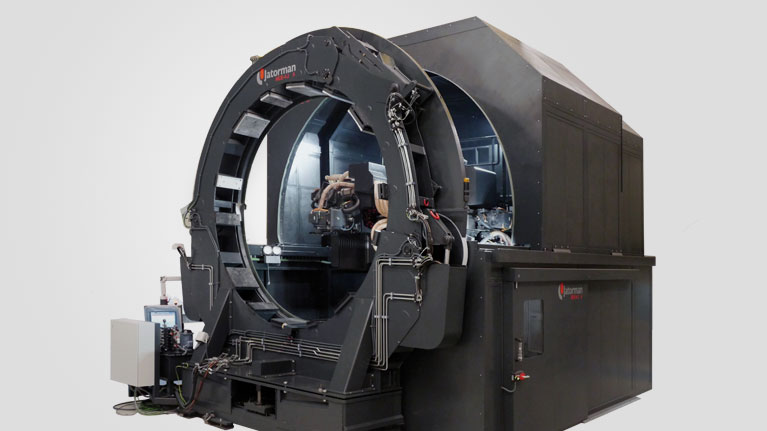

A machining and drilling centre for very large blades

Automated solutions in the assembly lines of wind turbines, placing a special focus on the production of larger blades in order to increase energy collection.

JATORMAN and Tekniker are designing and developing a machine that shortens the duration of high precision machining operations involving wind turbine blades measuring up to 75 metres in length.

The production of larger blades (measuring over 60 metres in length with maximum 4 m inner diameters) means more manufacturing difficulties will be experienced in terms of handling and accuracy.

To address this challenge, the Navarre-based company JATORMAN (specialised in handling and moving large and heavy loads) and the Tekniker technology centre have jointly developed a solution to design and build an innovative machine for the drilling and machining wind turbine blades.

This solution stands out because of its speed, versatility and resilience to accommodate elements of different sizes. Consequently, the equipment can automatically machine parts with a maximum length of 75 metres in length and an outer diameter of 4.2 metres with a degree of accuracy that is 40% higher than levels reported nowadays. On the other hand, machining operations can be shortened by up to 60% compared to other systems currently in use.