Aluminium surfaces with antifreeze ability

Development of aluminium surfaces with antifreeze ability

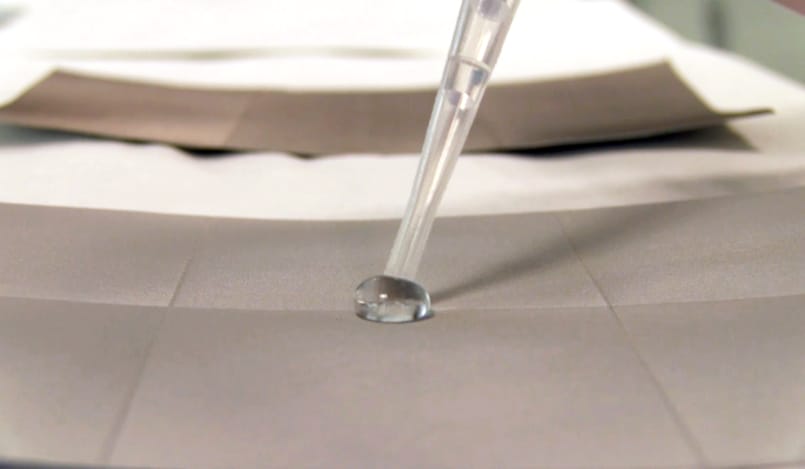

Obtaining superhydrophobic surfaces with properties retardant to ice formation. Also, surfaces have been developed which induce the change of refrigerant phase through the deposition of Sol-Gel coatings.

The main objective was the development of Sol-Gel coatings on substrates of aluminium, copper and stainless steel with differentiated properties, such as anti-ice on aluminium, to prevent the formation and accumulation of ice in HVAC (Heating, Ventilating and Air Conditioning) systems exposed to extremely cold conditions in northern European countries.

Also, surfaces have been developed which induce the refrigerant phase change (liquid to gas) used in HVAC systems through the deposition of Sol-Gel coatings.

The final solution for the development of antifreeze coatings consisted of the combination of consistent technologies with microstructuring by laser followed by a Sol-Gel coating deposition.

In this way, superhydrophobic surfaces have been achieved with static contact angles 140°C and rolled angles close to 0°C, which retard the formation of ice on the metal.

Moreover, the final solution for developing surfaces that encourage the phase change of refrigerants is based on a selective Sol-Gel coating which facilitates heat transfer.

The EnE-HVAC (Energy efficient heat exchangers for HVAC applications) project objective within which this case was framed, focused on applications for HVAC air conditioning systems, although it is demonstrating that this type of surface may have applications in other sectors such as those of energy, automotive, and construction, among others.