Basque know-how for the world’s most advanced telescope

The IK4-TEKNIKER technology centre is to play an outstanding role in the development of the Large Synoptic Survey Telescope (LSST) to be commissioned in Chile in 2020.

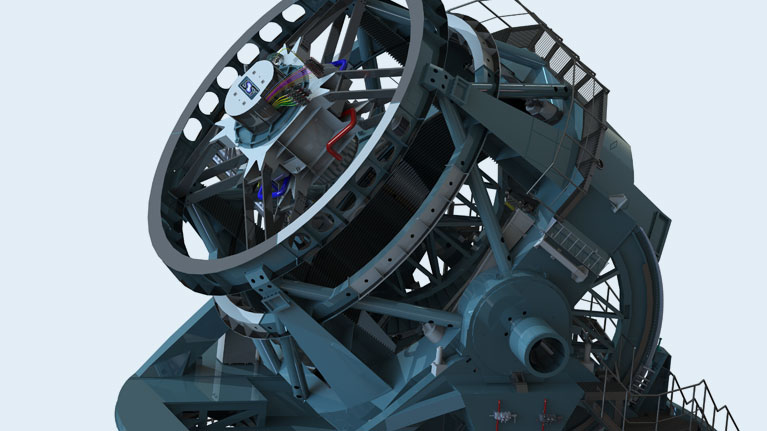

Mapping the entire sky visible from planet Earth by means of high precision images. This is the ultimate goal of the Large Synoptic Survey Telescope (LSST), an ambitious international project that is to incorporate Basque know-how. In fact, IK4-TEKNIKER, the Basque Technology centre, will be involved in the design and development of control and safety systems, will ensure camera cable rotation and deliver protective roofing for the mirrors to be fitted on this state-of-the-art scientific installation.

It has been estimated that the LSST will be commissioned in 2020 at Cerro Pachón situated in the Chilean desert of Atacama and equipped with an 8.4 m dia mirror (i.e., as wide as a tennis court) designed to examine the entire visible sky.

The equipment installed will allow the sky to be scanned every 3 or 4 nights to deliver a picture forty times larger than that of a full moon thanks to a 3,200 megapixel camera. The telescope itself, to be installed at an altitude of 2,700 metres, will perform real-time image analyses and detect any significant variations.

This will allow for the identification of any elements that have either changed or moved; from supernova explosions in other parts of the Universe to asteroids that could crash against the Earth.

The IK4-TEKNIKER contribution

In cooperation with the engineering firm Empresarios Agrupados entrusted with developing the telescope’s main structure, the Basque technology centre is to design and develop the control system, one of the unit’s key elements as it allows precision and repetitiveness requirements to be met in full in terms of aiming the telescope according to values than one arc second (1/3600 degrees).

The main difficulty the LSST telescope must cope with is related to high dynamic motion requirements involving its main axes (azimuth and elevation) so that different areas of the visible space can be photographed in the shortest possible amount of time.

For motion to occur according to the above mentioned dynamic requirements, the control system must be able to quickly attenuate any vibrations produced once the axes move and then photograph the area the telescope is aimed at immediately.

Both controlled main axes are made of components that go beyond the currently available state-of-the-art developments and this explains why tailor-made designs have been used for this telescope.

Therefore, each axis rests on hydrostatic bearings, is driven by linear motors laid out in a peripheral circular pattern. Their position is measured by optical devices with a layout similar to that of the drive motors featuring a number of characteristics in terms of accuracy, repeatability and resolution that are absolutely unique considering their size.

From control to safety

In addition, IK4-TEKNIKER will develop a system that will allow for safe telescope operation to safeguard the sizeable investment made and guarantee operator safety at all times.

This system will monitor travel limits, excessive speed, emergency pushbuttons and the correct operation of all components.

The technology centre will also provide know-how to develop a rotator for the camera cables, a mechatronic device that winds or unwinds cables and tubing connected to the camera when in rotation or taking photographs.

Finally, the technology centre will also provide mobile protective roofing for the main mirrors by designing another innovative mechatronic system to protect optics against falling objects, rain or dust.

The experience gained by IK4-TEKNIKER in terms of ultra-precision has allowed the technology centre to become a benchmark supplier to major international scientific facilities such as the Large Telescope of the Canaries (GTC), the European Synchrotron Research Facility (ESFR), the Institute Laue Langevin neutron accelerator (ILL), the ISIS experiment at Oxford University or the Spanish Metrology Centre.

Beyond the Hubble

The LSST project is being carried out by a consortium established by the University of Arizona, Washington University, the Research Corporation for Advances in Science and the Association of Universities for Research in Astronomy (AURA).

The consortium, with headquarters in Tucson (USA), has brought together thirty or so universities, scientific centres and specialised laboratories.

The construction of the telescope, with an estimated cost of approximately 700 million dollars, is the outcome of a private-public partnership involving one hundred astronomers, physicists and engineers that are collaborating to transform a piece of equipment into a reality that will allow us to take gigantic steps with regard to our knowledge on stars.

In 2008, the former Microsoft executive Charles Simonyi and the founder of the corporation, Bill Gates, donated 20 and 10 million dollars, respectively, to the project.

Once commissioned, it will only take the equipment installed a few days to obtain the same amount of information that, in the case of the well-known Hubble space telescope, requires 120 years. At full performance, the telescope will be capable of taking more than 200,000 photographs per year.

“With its capacity to detect weak objects and look into the remotest corners of the Universe, the LSST has been designed to deal with some of biggest challenges related to astronomy”, once stated the director of the project, Steven Kahn.